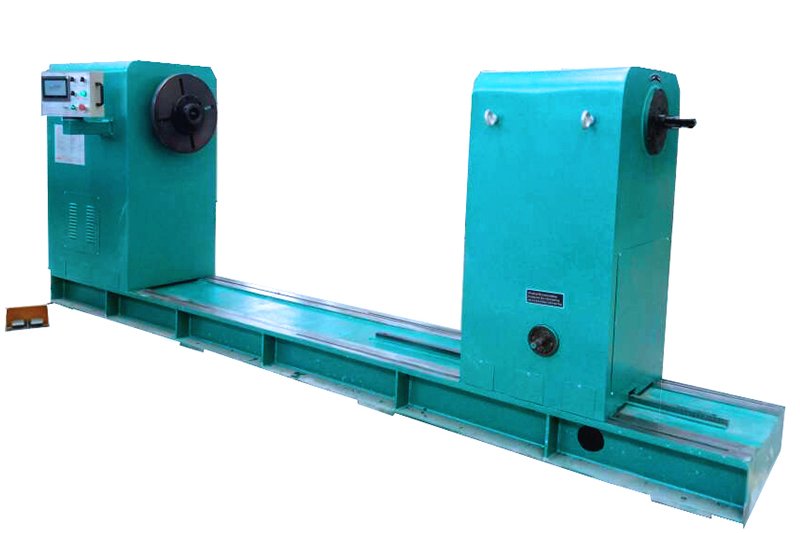

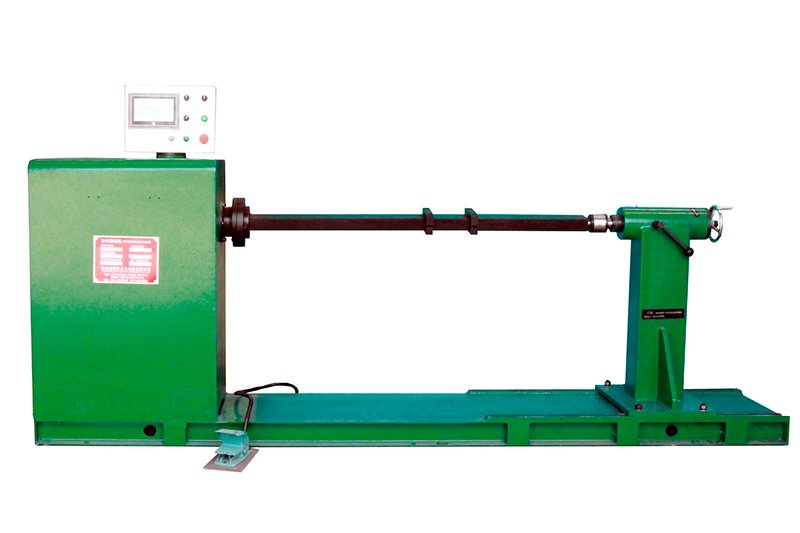

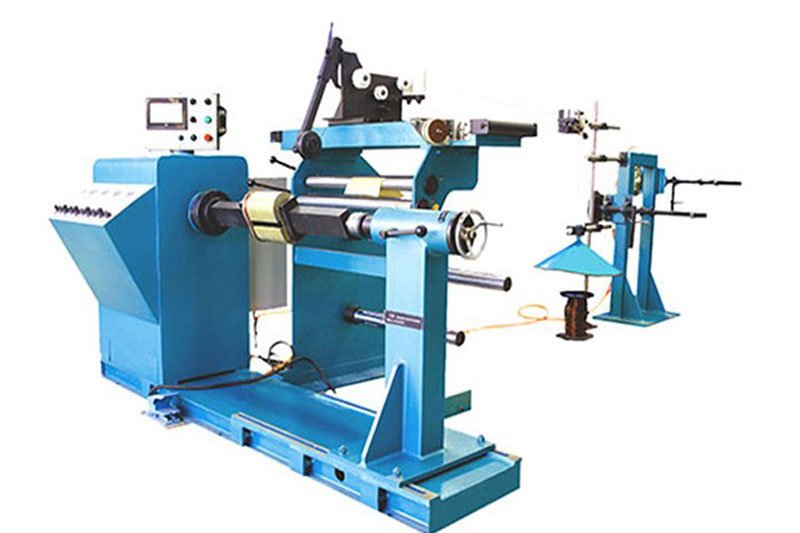

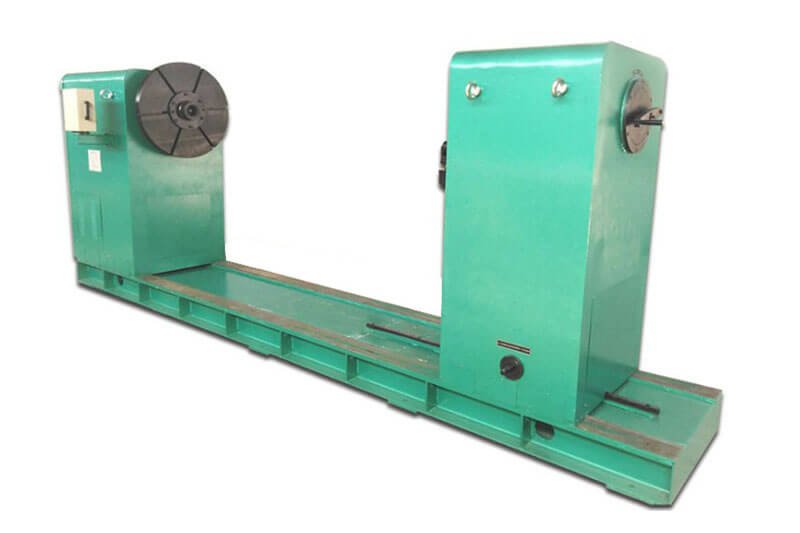

Winding Machine for Transformer is one of the special equipment necessary for the winding operation of transformer coils. Its use frequency and operating intensity are very high. The transformer winding machine has considered such high strength from the design, manufacturing, configuration and other aspects. How to maintain daily for it is very important.

The main components of the winding machine

To understand how to maintain the equipment, we should be familiar with the structure of the winding machine.

Only by understanding the components of the equipment can we routinely maintain the equipment.

winding machine for transformer mainly include:

The body, the main shaft drive system, the coupling mechanism, the tailstock support, the numerical control system, the speed control system and other components.

General lubrication cleaning

The regular lubrication of the transmission parts of the equipment is the most conventional maintenance content.

If the equipment has an abnormal jamming and unsmooth operation, we should lubricate it.

we should clean the equipment every day.

The electrical circuit board and count sensor will appear in the controller system if a large amount of dust is collected.

Transmission adjustment

the adjustment of the transmission system is mainly the adjustment of the tightening force of the transmission belt, the inspection of the wear of the pulley, the inspection of the oil level of the reducer, etc .;

Brake adjustment

The control of the parking position accuracy depends entirely on the work of the brakes.

After long-term frequent work of the brake, the brake pads will be worn to a certain extent.

The position of the brake pads needs to be adjusted in time to ensure normal braking torque.

Leave A Comment