well known, As key equipment in the distribution network, The safety, reliability, and economy of dry-type transformers are of great significance to the reliable and economical operation of power systems. With the global emphasis on “building a resource-saving and environment-friendly society”, ECO development, Circular development, and Low-carbon development become mainstream. For electrical product manufacturing, It is necessary to consider the impact of the material selection, production, sales, use, and recycling of products on the resource environment.

The three-dimensional wound core open dry-type transformer, which perfectly combines the advantages of the three-dimensional wound core technology and the open winding structure process, conforms to the direction of green manufacturing and has unique advantages.

The following article mainly expounds on the structural technology and performance characteristics of the three-dimensional wound core open dry-type transformer.

Structural characteristics of wound core in open dry-type transformer with three-dimensional wound core

The three-dimensional wound core three-phase transformer has the shape of a symmetrical triangle, and the magnetic circuit distribution is the most ideal, which avoids the defect of more air gap leakage in the asymmetric core structure of the conventional laminated core.

The three-phase magnetic circuit of the three-dimensional wound iron core has the same length, and the direction of magnetic conduction is exactly the same as that of the magnetic circuit of the iron core.

There is a balanced magnetic flux on the three-phase column to reduce excitation current and surge current.

Due to the tight winding without air gap and annealing treatment, the vibration and sound level of the three-dimensional wound core are greatly reduced, and the noise can be reduced by 8dB to 25dB compared with the conventional laminated core.

Due to the advantages of the structure, under the same performance requirements, the three-dimensional wound core usually saves more than 20% of silicon steel material than the traditional laminated core.

Weight comparison between three-dimensional wound core and laminated core

The three-dimensional wound core is on average about 20% lighter than the laminated core.

In addition to reducing the waste of the corner waste of the laminated core by about 3%, the three-dimensional wound core saves an average of about 23% of the silicon steel sheet compared with the laminated core.

In addition, the space-filling factor in the cross-sectional area circle of the three-dimensional wound core column is 4% to 6% higher than that of the laminated core.

When the effective area AC is the same, the diameter of the wound core column will be less than 2 to 3% of the diameter of the laminated core, which can make the coil The wire length is reduced by 2 to 3%, which can not only save copper and other raw materials but also reduce the load loss.

Coil structure characteristics of three-dimensional wound core open dry-type transformers

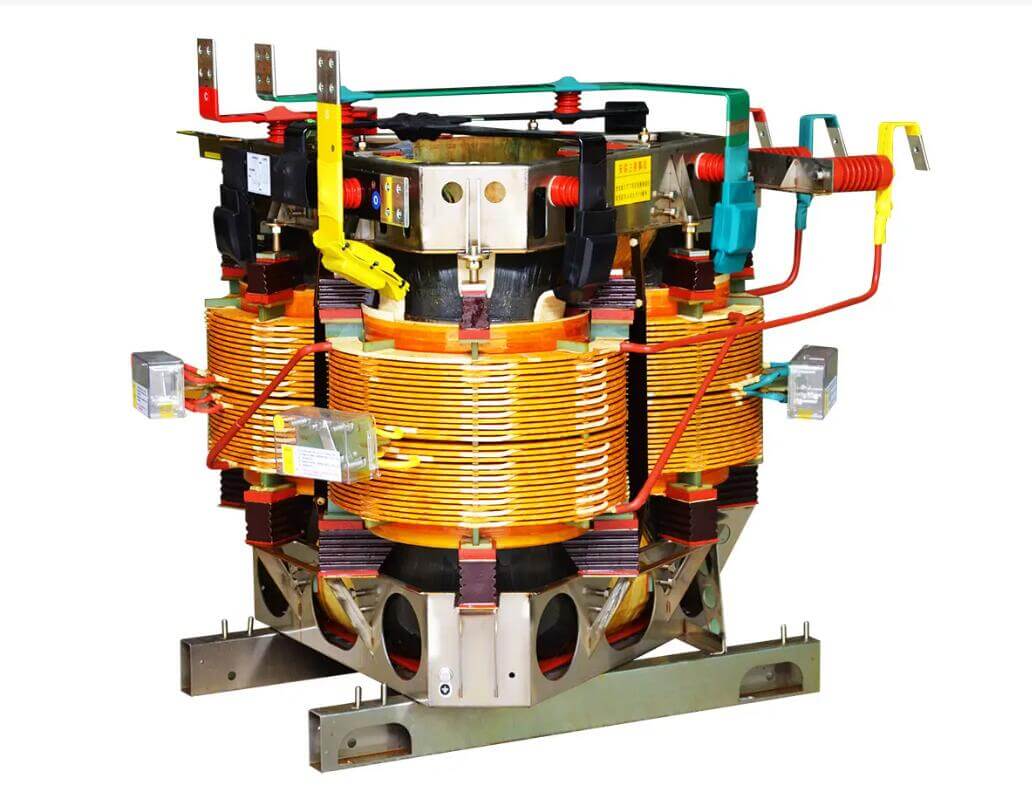

The three-dimensional wound core open type dry-type transformer has the advantages of saving material and low no-load loss in addition to the core, and the structure of the coil is also quite characteristic.

Generally, the low-voltage winding adopts a foil coil structure, which is convenient for winding and has high mechanical strength.

The high-voltage winding adopts a pie-type coil structure, which has good heat dissipation and high mechanical strength.

The high and low voltage coils are separated by an insulating cylinder.

The thin insulating cylinder is added with an air-channel structure.

The insulating material with a dielectric constant close to that of air is used, and the electric field is evenly distributed, which reduces the possibility of partial discharge.

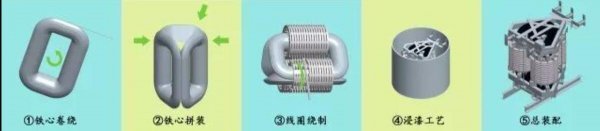

The production process of three-dimensional wound core open dry-type transformer

The main production process of the three-dimensional wound core open dry-type transformer is core manufacturing, coil winding, dipping, and assembly.

If you are familiar with the winding manufacturing of a three-dimensional wound core, from the perspective of total labor time, the production of a three-dimensional wound core open dry-type transformer is close to that of a conventional laminated core transformer.

Three-dimensional wound core open type dry-type transformers require less time for core winding, core, and coil assembly, but more time for coil winding, so the total time is almost the same as the time required for conventional laminated core open dry-type transformers.

The trend of electrical equipment is energy saving, environmental protection, high reliability, and safety.

According to the need for green development of society, three-dimensional wound core open dry-type transformers conform to this global trend and provide additional benefits to end-users.

For low losses and low carbon emissions, energy conservation regulations and standards should reflect the requirements of green development and less resource consumption.

The application requires more three-dimensional wound core open dry-type transformers with high reliability, safety, good resource-saving ability, and high overload capacity.

The three-dimensional wound core open type dry-type transformer technology will be more applied to amorphous alloy transformers, special transformers, and large transformers to maximize the benefits of the three-dimensional wound core technology.

In recent years, with the development of silicon steel and amorphous alloy materials, and with the development of insulation design and insulation materials, dry-type transformers with lower no-load loss, fewer materials, lower production costs, and longer service life have broad prospects for development.

Leave A Comment