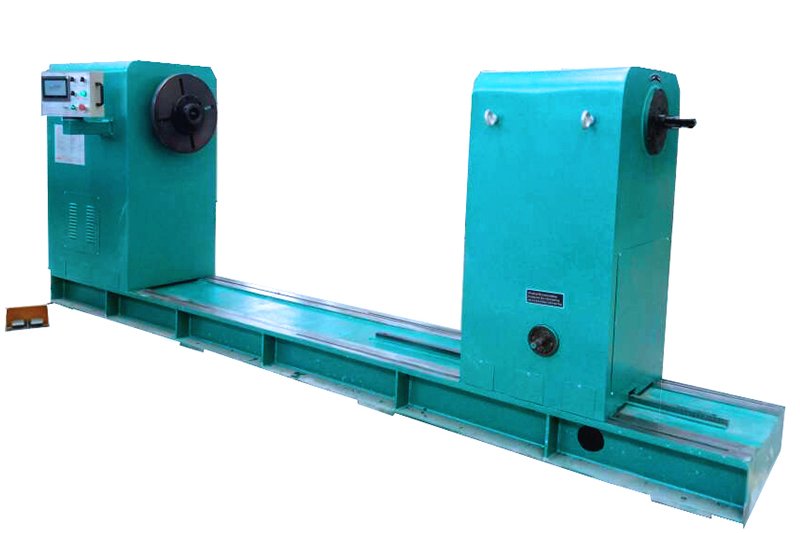

Distribution Transformer Winding Machine

Model:RX-5

It is heavy duty models for winding transformer and electric motor coils. max. capacity for 63000kva.suitable for round or rectangular wires,winding into round,oval or rectangle shape coils.you can find the right machine for almost all needs. We also provide customized coil winders built to customer requirements.if you look for automatic wire winding machines or foil winding machine,please check them.

Features for Distribution Transformer Winding Machine

1.The main box and the base are integrated. It is easy for installation and ensures that the top of the main box and the tail box are concentric, equal in height, and not need to pouring foundation,Use expansion bolts to fix on the 250mm cement floor can operate the machine.

2. The main shaft bearing of the main box and tailstock box is selected at least 8 times the net load technical requirement. For example, RX-3 is a 3 ton winding machine with 3007220 type bearings, inner diameter 100, outer diameter 180, and netload 30T. The internal quality of the whole machine is greatly improved, the operation is stable, the noise is reduced by one third, and the winding die diameter The runout is less than 0.3mm

3. In order to ensure the safety and quality of the tailstock sleeve, the diameter of the tailstock sleeve is more than 5 times larger than the diameter of the traditional sleeve, and the net load is increased by more than 5 times. The movement of the sleeve adopts a T-shaped thread, which is moved and locked in a handle Completed last time. The locking is deadlocking, which is much higher than the general sleeve outer circle locking safety factor, which is truly flexible in movement and secure in locking.

4.Convenient tail box moving structure

Adopting German technology and transmitting through the turbine box, the torque is large, and the box can be moved easily and smoothly with only one handle, which saves time and effort and ensures the symmetry of the head and tail boxes.

5.Adapt to the connection mode of various winding dies

The current transmission modes of the head and tail box to the winding die are: faceplate type, top type, concave cam type, square hole type, cam top type, etc.

6.Chain drive promotes the upgrading of winding machines

The characteristics of the winding machine are smooth starting, fast braking and flexible braking. The traditional winding machine is driven by a gearbox. When the operator needs to stop the machine, it cannot stop and cannot be turned immediately when it needs to be driven. Now we have adopted a chain and gear drive to solve this problem and have a long service life. Chain drive Type winding machine, convenient and reliable to operate.

7.Maintenance-friendly double door structure

There are two doors behind the main box. The electrical components you see when you open the first door are convenient for electricians to repair; when you open the second door, you can see mechanical transmission parts, which is convenient for mechanical maintenance workers. maintenance. You can also open the second door directly, which is easy to unlock.

8.Reliable electrical operating system, first-class electrical components

The host adopts imported Mitsubishi frequency converter and PLC method to realize the stepless speed regulation of motor transmission. The angle signal of photoelectric encoder is calculated by PLC to achieve accuracy, display and control displacement, and frequency converter control. The motor adopts self-locking system to adjust the braking time at will. It adopts Japanese Mitsubishi inverter for speed regulation, which is convenient and flexible. At the same time, Mitsubishi programmable controller and Mitsubishi touch screen display can realize accurate and reliable control of the whole machine.

Composition

main axis box

- The transmission part is in the spindle box. The power is output by the motor, transmitted to the reducer through the pulley, and transmitted to the spindle through the chain. Finally, the winding mold is rotated by the winding mold connection disk in the front section of the spindle.

End Box

- The end box can move 0-200mm back and forth on the base. The T-screw is used for back and forth movement. Locking and moving are completed by the moving handle, which is very flexible and reliable.

bottom seat

- Welded with high-quality steel plate and H-beam, it is an integrated structure, which ensures the strength and accuracy of the whole machine and improves machine’s stability.

control system

Main component and supplier

| Name | Supplier 1 | Supplier 2 |

| frequency converser | Mitsubishi | Inovance |

| Programming controller PLC | Mitsubishi | Inovance |

| Touching screen | Mitsubishi | Inovance |

| Foot switch | Taiwan | Taiwan |

| Power button | Schneider or DELIXI | Schneider or DELIXI |

| No. | Item | Parameters |

| 1 | Type | RX-5 |

| 2 | Max bearing weight | 5000kg |

| 3 | Winding speed | 0~30rpm |

| 4 | Spindle center height | 1300mm |

| 5 | Motor power | 7.5kw |

| 6 | Distance between main axis and end box | 1000-2500mm |

| 7 | Other accessory | Protection cover for main axis box,bracket for end box

Not include expandable mandrel |

Your Content Goes Here

$9000 – $15000 / Set FOB QINGDAO

MOQ: 1 Set

Shipping: Support Sea

freight lead Time:

Quantity(Sets) 1 – 1 >1

Est. Time(days) 45 Negotiable

After-sales Service Provided: Field maintenance and repair service, Field installation

[contact-form-7 id=”193″][/contact-form-7]