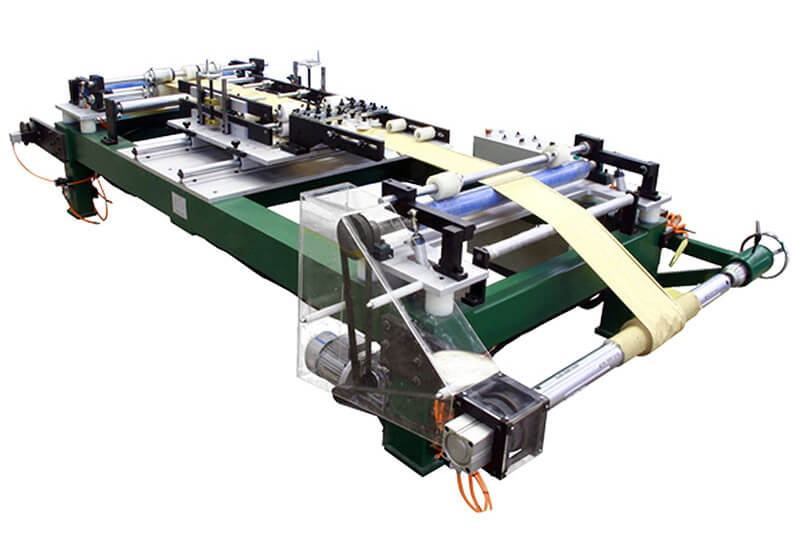

Insulation Paper Folding Machine

It is mainly used for insulation layer’s edge fold in Distribution transformer coil winding,which form an edge insulated structure in insulation layer’s left and right edge.highly improve coil mechanical strength,winding efficiency and lower material cost.

Configuration for Insulation Paper Folding Machine

1)Insulation layer decoiler

- A detachable air-expanding roller is used, and a positioning connection hole is provided on the rotating short shaft to link the air-expanding roller. The rotary short shaft is equipped with a pneumatic damper, which can easily adjust the size of the damper to control the tension of the paper tape.

2)guiding device

- It consists of a set of stainless steel rollers, oblique drawing rollers, and guides. It guides the insulating paper not to deviate, and makes the insulating paper taut horizontally, which is convenient for pinhole forming processing.

3)pinhole forming device

4)edge folding passage

- The channel is composed of a fixed bracket, a movable bracket, left and right slide tables, forming wheels.

5)shape pressing device

- Five pressure rollers with different angles are respectively arranged on the left and right fixing brackets. The zigzag folds that have been formed on the two sides of the insulating paper are horizontally formed by these pressing wheels, and are closely pressed against the surface of the insulating paper to be finally formed.

6)belt pulling device

7)winding device components

8)electrical system and pneumatic system components

main accessories:

| Frequency changer | Schneider |

| Electrical element | Schneider |

| pneumatic components | ATRATC(Taiwan) |

| Insulation layer roll specification | Inner hole diameter:76mm |

| Outer diameter less than or equal to 400mm | |

| Shaped paper roll specification | Inner hole:76mm |

| Outer diameter less than or equal to 400mm | |

| width for Insulation paper | 160-800mm |

| Insulation paper thickness | 0.08-0.23mm |

| Edge folding layer quantity | 3 layers(including bottom layer) |

| Edge folding width | 7mm/10mm(standard) |

| Working efficiency | |

| Speed of edge folding in shape | 0-20m/min(frequency without grade adjustment |

| Knife outer diameter | 84mm |

| Knife quantity | 8 pieces |

| Power requirement | |

| power | 1.1kw |

| Electrical power | 3 phase 4 wire,380v,50hz or make to requirement |

| Air supply | Air consumption 0.1M3/min |

| Air tube | PVC tube outer diameter 8mm |

| Whole machine covering area and size | 5000*2000*1100mm |

click to view other products:wire winding machines,foil winding machine

$9000 – $15000 / Set FOB QINGDAO

MOQ: 1 Set

Shipping: Support Sea

freight lead Time:

Quantity(Sets) 1 – 1 >1

Est. Time(days) 30 Negotiable

After-sales Service Provided: Field maintenance and repair service, Field installation

[contact-form-7 id=”193″][/contact-form-7]