| FOB Qingdao Price | $1700– $2400.00/ Set |

|---|---|

| MOQ | 1 |

| Lead time | 15 days |

| Warranty | 12 months |

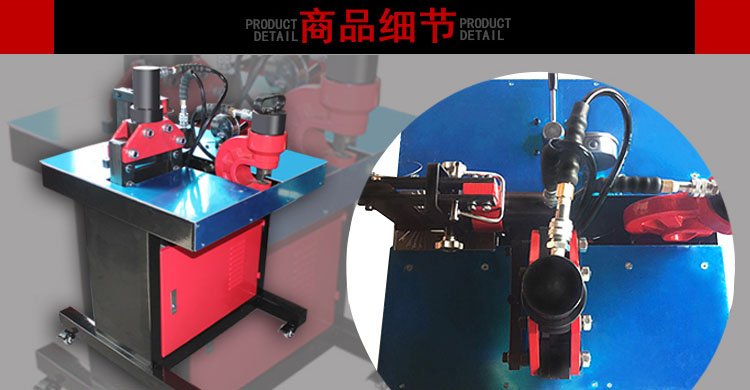

Hydraulic Busbar Bending Machine

Technical parameter of Hydraulic Busbar Bending Machine:

| Three functions | DHY-150

Cutter (CWC-150) Puncher (CH-60) Bender (CB-150D) |

DHY-200

Cutter (CWC-200) Puncher (CH-70) Bender (CB-200A) |

| Mobile table size | 700*700*1100mm (L*W*H) | 850*750*1100mm (L*W*H) |

| Input voltage | Single phase, 50HZ,220V(380V) | |

| Machine total weight | 170 KG | 200 KG |

| Rated working oil pressure | 700KGF/CM2 10000PSI | |

| Processing thickness range | 3-10mm of copper and aluminum busbar

3-6mm of Iron plate |

3-12mm of copper and aluminum busbar

3-10mm of Iron plate |

| Cutter force | 20TON | 30 TON |

| Cutting and bending range | Copper and aluminum busbar ≦150*10mm | Copper and aluminum busbar ≦200*12mm |

| Bending force | 16T | 30T |

| Bending angle | 0-90 degree | |

| Punching force | 31 TON | 35 TON |

| Distance from hole center to edge of busbar | 95mm | 110mm |

| Standard punching dies | Φ7mm,Φ9mm,Φ10.5mm,Φ13.8mm,Φ17mm,Φ20.5mm

Other size can be customized |

| Other accessories | |

| Can be equipped with Embossing | Busbar ≦150*12.5mm working force:55T working stoke:26mm

Net weight: 38KG |

| Equipped with 300 type Crimping Tool | Crimping range:16-300mm2 Max.working stoke:20mm

Crimping tool weight: 15KG Mold: 16, 25, 35, 50, 70, 95, 120, 150 ,185, 240, 320, 400mm2 |

| Equipped with 400 type Crimping Tool | Crimping range:16-400mm2 Max.working stoke:22mm

Crimping tool weight: 16KG Mold: 16, 25, 35, 50, 70, 95, 120, 150 ,185, 240, 320mm2 |

| Equipped with flat and vertical bending tool | Max. Working stoke: 200mm bending range: copper and aluminum busbar width 40, 50 ,60, 80, 100, 120mm Thickness:4-12mm

Bending angle: D>90 degree any angle Bending radius R=bubsar width *2.5 Weight:80 KG |

Technical Details of Hydraulic Busbar Bending Machine:

1.Independent working position, bending, punching, cutting, etc. do not interfere with each other, which greatly improves work efficiency

2.High-precision punching die frame to extend the service life of the die.

3.Equipped with a scale table to read the bending angle, improve accuracy and avoid excessive bending

4.The hydraulic oil tank adopts thick steel plate welding and phosphating treatment, so that the oil tank will not be deformed after long-term use

5.The tubing is wrapped with damping material to prevent the tubing from twisting and breaking.

6.All-copper motor, high working efficiency and stable operation

7.360-degree displacement casters can facilitate mobile operations. Can also be locked and fixed.