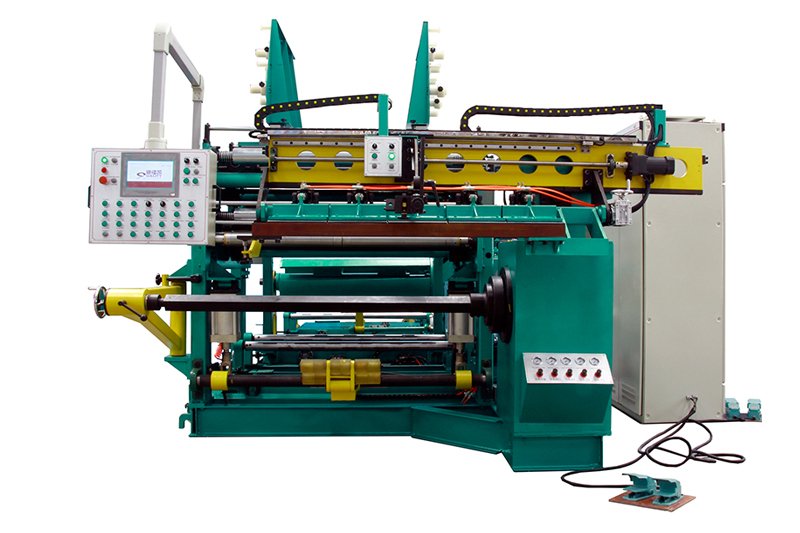

Foil Winders is designed to wind LV transformer coils.it can wind one or two foils made of cooper or aluminum.Uniform and continuous tension is provided during winding,ensures smooth and tight foil winding.

We offers various kinds of foil winding machine,wire winding machines,you can find the right machine for almost all needs. We also provide customized coil winders built to customer requirements

Features for Foil Winders

1.PLC control,easy for complete mass production.

2.The system can store up to 30 sets of coil data, convenient for operate.

3.constant tension control during all winding

4.equipped with a TIG device to weld.

5.Automatic deviation adjustment.

Composotion:

| 2-1 | foil decoiler | 1 set |

| 2-2 | foil feeding unit | 1 set |

| 2-3 | foil cleaning unit include burr and dust clean | 1 set |

| 2-4 | centering guide | 1 set |

| 2-5 | winding device | 1 set |

| 2-6 | Wound coil pressing device | 1 set |

| 2-7 | lead bar TIG welding device | 1 set |

| 2-8 | foil cutting device | 1 set |

| 2-9 | layer insulation decoilers | 2 sets |

| 2-10 | edge filling strip units | 12 sets |

| 2-11 | PLC control panel | 1 set |

BRJ-1100-2

- Aluminum Foil: Min 0.5mm to max. 2.5mm

- Copper Foil: Min. 0.3 mm and Max. 2 mm

- Width: Min. 180 & Max. 1100mm

- Coil outer Dia: 1000 mm

- maximum Winding Speed: 0 to 20 RPM continuously

- Type Of Welding: Tig Welding

- No of Foils: 1 or 2(Max)

- Type of coil: Round, Rectangle and Oval Shape

$30000 – $50000/ Set FOB QINGDAO

MOQ: 1 Set

Shipping: Support Sea

freight lead Time:

Quantity(Sets) 1 – 1 >1

Est. Time(days) 30 Negotiable

After-sales Service Provided: Field maintenance and repair service, Field installation