| FOB Qingdao Price | $17000.00 – $20000.00/ Set |

|---|---|

| MOQ | 1 |

| Lead time | 60 days |

| Warranty | 12 Months |

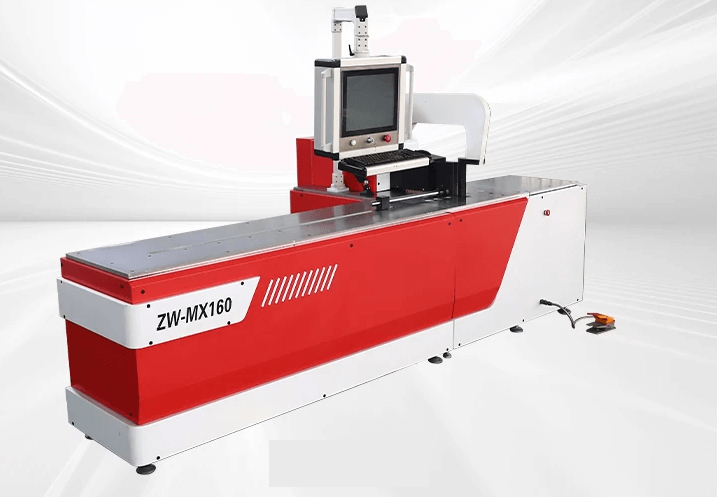

Busbar Bender

This series of CNC busbar bending machines are high-efficiency, highly automated, and high-precision busbar processing equipment used for bending copper and aluminum busbars. The products are widely used in high and low voltage switchgear, transformer manufacturing, box-type substations, bus ducts and other power and electrical industries.

2.Selection of main accessories

| 1 | servo motor | Yaskawa | 1 | 2 | Programmable controller | Siemens, Germany | 1 |

| 3 | Screw/Guide Rail | HiSilicon/TBI | 2 | 4 | Industrial switches | TP-LINK | 1 |

| 5 | Precision planetary reducer | Titanium Mag | 1 | 6 | Industrial Computer | Beijing Qiyang | 1 |

| 7 | electrical components | Schneider | 2 |

Equipment parameter comparison of busbar bender

| 1 | Nominal pressure | KN | 400 | 2 | Main motor power | KW | 5.5 |

| 3 | Bending angle | . | +/-0.3 | 4 | Spindle travel | mm | 210 |

| 5 | Stopper accuracy | mm | +/-0.15 | 6 | Maximum size of flat bend | mm | 16*160 |

| 7 | Maximum size of vertical bend | mm | 12*120 | 8 | Stopper length | mm | 1500 |

| 9 | Machine weight | KG | 3350 | 10 | Dimensions | mm | 3450*1200*1750 |

Random accessories

| 1 | R3Flat bending mold | 1 | 2 | R5Flat bending mold | 1 |

| 3 | R60Vertical bending mold | 1 | 4 | R100Vertical bending mold | 1 |

| 5 | Random Tools | 1 | 6 | Instruction manual/factory report | 1 |

2.Performance and characteristics

2-1,This machine utilizes a closed bending structure, with 80mm T10 steel plate, quenched and tempered, serving as the primary load-bearing platform. The servo motor is mounted on this platform, offering advantages such as simple structure, optimal load distribution, convenient material handling, and excellent visibility.

2-2 In the bending unit, a high-inertia servo motor serves as the primary power source, powering the high-precision planetary reducer and ball screw.

2-3 The electrical system utilizes a touchscreen human-machine interface and a proprietary bending program, offering a clear interface and simple structure.

2-4 In terms of software, this machine can independently draw 3D graphics and provide real-time operation simulation and monitoring, offering enhanced intuitiveness. It can also be used in conjunction with CJ-MX-603 CNC programming software, offering simple operation, independent machine and software interference, and easy maintenance. This CNC programming software, independently developed by our company, is specifically designed for automated busbar processing.