| FOB Qingdao Price | $5900.00 – $11000.00/ Set |

|---|---|

| MOQ | 1 |

| Lead time | 20 days |

| Warranty | 12 Months |

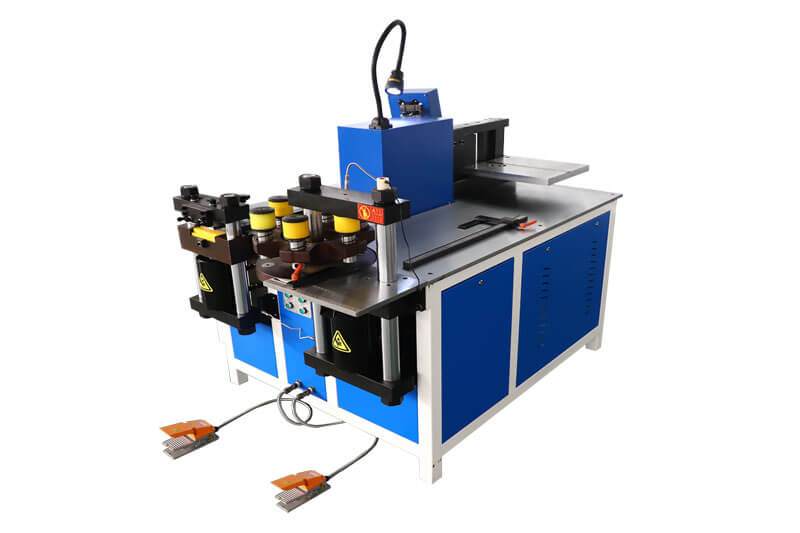

Bus bar Bending Machine

It is special machine for cutting,bending and punching on aluminum and copper bus bars.

Main features :

It combines punching, bending, and cutting, as well as other functions such as embossing, twisting, flattening, and pressing tie-in.

Three electric motors and pumps ensure that workers can operate the cutting unit, punching unit, and bending unit simultaneously.

- Cutting unit:it uses punch shearing,the incision interface is flat,no droop and burrs and waste, beautiful shape.

- Punching unit:uses an united SIX-mode turn plate in tooth shape to make sure the upper mold and the lower mold are absolutely in the same center,improving the mold concentricity and longtening the working life. The turnplate is in tooth shape with good view and high strength. No need to frequently change molds, labor intensity is highly reduced. It is easy and quick to use.Producing efficiency is obviously higher than a traditional one.Newest Update:add table with ruler and Laser alignment on punching unit, Double positioning to ensure the accuracy of the punching positionBending unit:

.CNC PLC control system,just input a angle on the touch screen, it can be bending automatically.Angle bending accuracy: +/- 1°

‚double worktable.ensures three unit can real working at the same time.

Technical parameter of Bus bar Bending Machine

ZTMX-303K ZTMX-503K ZTMX-803K Punching Max power (KN) 300 500 800 Punching Diameter (mm) Ф4.3-Ф25 Ø4.3~34 ф4.3~ф36 Max thickness (mm) 12 16 20 Max width (mm) 160 250 300 Shearing Max thickness (mm) 12 16 20 Max width (mm) 160 250 300 Bending Max power (KN) 300 500 800 Max width (mm) 160 250 300 Max thickness (mm) 12 12 20 Vertical Bending Max width (mm) 100 (10mm thick copper)

120 150 Min. bending angle degree 90° 90° 90° Embossing √ √ √ Pressing Cable Joint √ √ √ Twisting √ √ √ Outline Dimensions 1300x1000x900 1850x1500x1400 2050*1600*1650 Main motor power (KW) 3×4 3×5.5 3*7.5 Price Include bending, punching and cutting USD5900-7000/SET FOB QINGDAO with Panasonic PLC or SIMENS PLC USD7500-8500/SET FOB QINGDAO with Panasonic PLC or SIMENS PLC USD9500-11000/SET FOB QINGDAO with Panasonic PLC or SIMENS PLC 4.included mould list:

No. Name Unit quantity 1 Punching mould Sets 6 2 Cutting mould Set 1 3 bending mould Sets 3 (R3,R5,R10) 4 Embossing mold Set 1 5.Main component:

PLC SIEMENS Panasonic Panasonic Relays Schneider Schneider China brand Contactors Schneider Schneider China brand Main driving motors Taiwan Taiwan China brand Oil pumps Taiwan Taiwan China brand Electromagnetic valves and overflow valves Taiwan Taiwan China brand -

Payment term:

30% deposit and the balance paid before shipment.

7.Delivery time: 20 days after deposit received.

8.More Info.

- Video link:https://www.youtube.com/watch?v=yohTaryueUI

- S.Code:8462490000

- Package:inner with waterproof stretch film,outer with sea export wooden box

-