Core Coil Assembly Table

Model:QZT-3/QZT-5

It is professional equipment for body assembly of amorphous alloy core transformer,it can be used for oil immersed and dry amorphous transformer installation.

Introduction for Core Coil Assembly Table

it changes traditional assembly technology,but put winding on the lift platform of assembly table in advance,axis of winding keep horizontal,each single frame iron core pass through inner hole of winding in transverse.and other process like iron core combined,bind up and close,body insulation assembly,clamp components tightening will be finished on assembly platform.during assembly,the height of this platform can be adjusted conveniently to satisfy assembly requirement of different process.

Composition

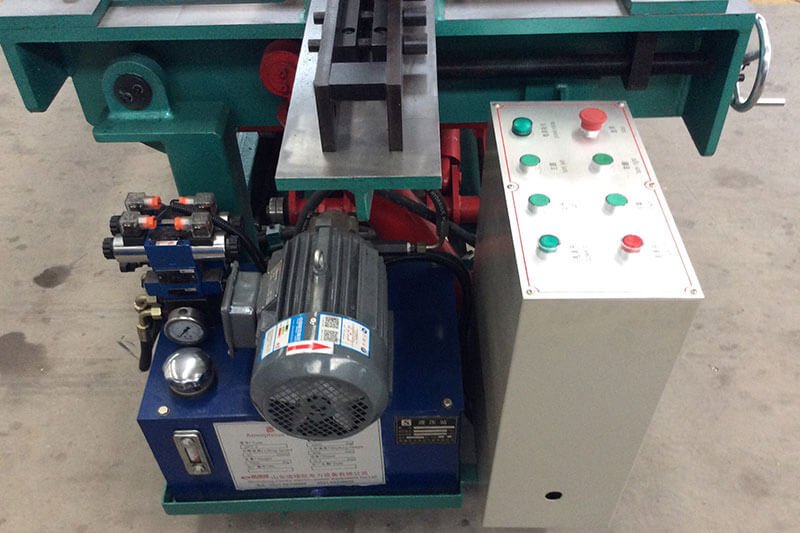

1.The lifting mechanism uses a hydraulic system, including: oil pumps, motors, and various types of valves. All are made in Taiwan, and combined modules ensure the system’s high reliability, low noise and no leakage.2.A large-sized lifting platform of 1350 * 800mm is set to meet the space required by various supporting institutions and Huatai devices.

3.The moving of the left and right sliding bearing platform adopts the pulley transmission method, which has strong bearing capacity, light operation and accurate positioning.

4.The front fixed platform is provided with a screw auxiliary transmission mechanism, and the fixed platform is moved forward and backward by shaking the hand wheel. After the platform enters the working position, you can lock the platform by pulling the handle

Equipment delivery status

Assembly machine one set (including electric control device)

Independent hydraulic lifting car one set

Documents with machine:

| numbers | items | Quantity |

| 1 | Packing list | 1 |

| 2 | Certificate of Conformity | 1 |

| 3 | operation instruction | 1 |

| 4 | The installation plan | 1 |

| 5 | electrical schematic diagram | 1 |

| 6 | pneumatic schematic diagram | 1 |

please check to view other products wire winding machines,foil winding machine,busbar machine.

| QZT-3 | |

| Load bearing(kg) | 3000 |

| Working height(mm) | 850 |

| Transformer out size using(mm) | L=700-1600

B=360-900 H=400-900 |

| Working stroke(mm) | 400 |

| Lifting speed | 40mm/s(adjustable) |

| Working pressure | P=14MPa |

| Overturn angle | 90 degree |

| Overturn speed | 90 degree/40s |

| Machine weight | 1500kg |

| Power | 2.2KW |

| Voltage | 380V,50HZ |

$9000 – $10000 / Set FOB QINGDAO

MOQ: 1 Set

Shipping: Support Sea

freight lead Time:

Quantity(Sets) 1 – 1 >1

Est. Time(days) 30 Negotiable

After-sales Service Provided: Field maintenance and repair service, Field installation