Are you looking for Busbar Bending Punching Cutting Machine?

200+ Happy CustomersWorldwide

Increase efficency 50%- 100%

Portable type, 3 in 1 type, CNC bending type

Basic operation in 3 days, Skilled in 7 days.

Get Quote in 12 hours

privacy policy: 100% Security and Privacy Guaranteed!

WELCOME TO SHUOHAO

Jinan Shuohao Machinery Equipment Co., Ltd is specializing in design, manufacture, train for transformer and switchgear making equipment.

Main products include busbar bending punching cutting machine, transformer coil winding machine, foil winding machine, , silicon core assembly table, amorphous core and coil assembly table, insulation paper folding machine, corrugated paper making machine, core coil reshaping machine.

Those products have been exported to Thailand, France, Vietnam, Myanmar, Pakistan, Australia, Turkey, India, Russia, and so on. Has more than 20 patents, Certificate of CE, ISO9001:2008 To satisfy customer after-sales service, the professional team responsible for training, guarantee customer products quality. Welcome old and new customers visit our factory!

Loved & Trusted By

Featured Busbar Machine Category

CNC Busbar Punching Shearing Production Line

This CNC busbar punching and shearing line seamlessly integrates automatic feeding, positioning, clamping, punching, shearing, embossing, die changing, and splicing. They offer a high degree of automation, precise positioning, and high reliability for copper and aluminum busbar processing.

They are widely used in high and low voltage complete sets, switchgear, transformer manufacturing, box-type substations, bus ducts, and other power and electrical industries.

CNC Busbar Bending Production Line

This machine utilizes servo motors and a Siemens CNC human-machine interface, coupled with our independently developed CAD/CAM software. It allows for on-site manual drawing of 2D and 3D drawings, one-click program generation, and automatic calculation of unfolded blanking lengths. It also supports importing 3D or 2D drawing files and is compatible with drawing software such as SolidWorks and AutoCAD. Its simple architecture and clear interface make it easy to learn and understand.

Optional bending tools enable flat bends, vertical bends, U-bends, and multiple bends.

CNC Busbar angle milling machine

It is a high-performance busbar processing machine featuring a high degree of automation, accurate positioning, ease of use, and stability. It seamlessly integrates automatic positioning, automatic clamping, and automatic angle milling.

It can automatically mill various common busbar angles. This machine is widely used for milling fillets and semi-circular arcs on copper and aluminum busbars in electrical switchgear and the power transmission and transformation industry, preventing the tip discharge problem that can occur with right-angle copper and aluminum busbars.

CNC Busbar Punching Cutting Bending Machine with gauging system

This machine uses a CNC system to control the servo motor, which can realize automatic material blocking and positioning for punching, shearing, and bending, CNC angle calculation, Z-bend calculation, calculation of unfolded material length, angle compensation, inertia compensation, press bending and pressure maintenance, and automatic start and stop of the main machine.

CNC Busbar Punching Cutting Bending Machine ZTMX SERIES

Suitable for bending, cutting, and punching on copper and aluminum busbar up to 16mm thickness and 250mm width.

PLC is controlled on the bending unit, just input an angle on the touch screen, and it can be bent automatically.Angle bending accuracy: +/- 1°

ideal for switchboard, busway, transformer, reactor and etc mass production, especially often requiring different angle bending.

Manual Busbar Punching Cutting Bending Machine DGWMX SERIES

Perfect for bending cutting and punching on max. 16mm thick and 250mm wide copper and aluminum.

double worktable. ensures three units can really work at the same time.

bending unit with Limit switch.

Used for switchboard,busway, transformer,reactor and etc mass production

Portable Busbar Punching Cutting Bending Machine

it used for punching, cutting, and bending on a max.12mm thick and 150mm wide copper and aluminum busbar.

Perfect for Power field, One-piece processing

Hydraulic busbar bending punching cutting machine DHY SERIES

Independent working positions, bending, punching, cutting, etc. do not interfere with each other, which greatly improves work efficiency.

High-precision punching die frame to extend the service life of the die.

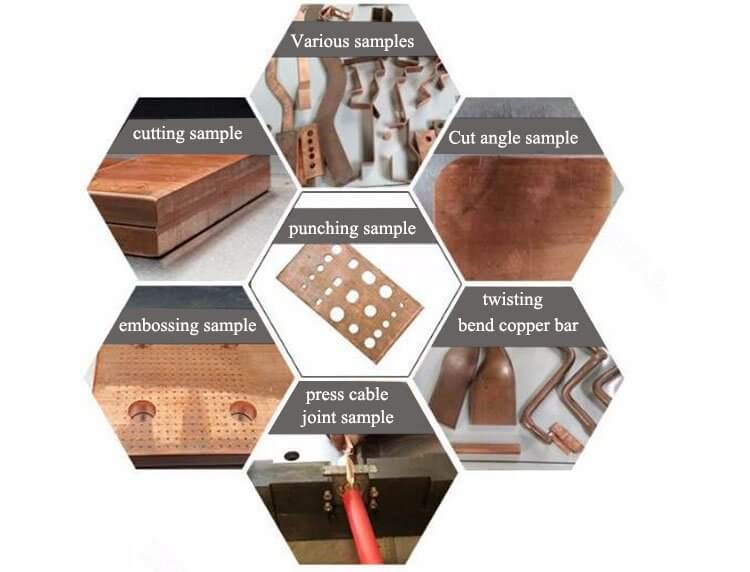

Processing Effect

Customer Site Reference

Customers Visit

Production Process

Get Quote In 12 Hours

Visit us

No.22 Luoer Industrial Park,Shizhong District,Jinan City,Shandong Province,China

Jinan City, Shandong, China

Call us

Just call us or add our whatsapp for easy communication.

+86 158 5315 2651

Contact us

Your email will be answered within 24 hours.

info@transformermachinemfg.com