SHUOHAO Winding Machine

Transformer Winding Machine

A transformer winding machine is a specialized piece of equipment used in the manufacturing of power and distribution transformers.

Transformer Winding Machine Key Types and Features

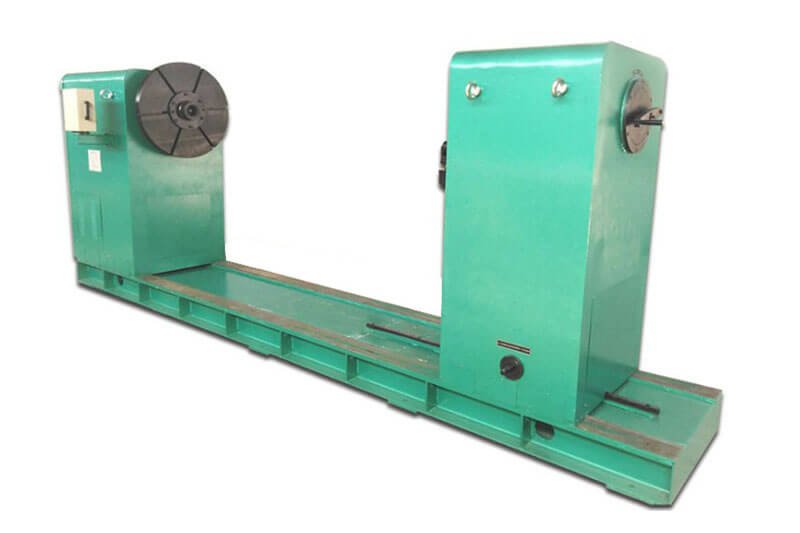

- Manual transformer winding machines–

These transformer winding machines are operated by a motor and counter. The turns you have wound will be showed in the counter. It is easily operate by a foot pedal.

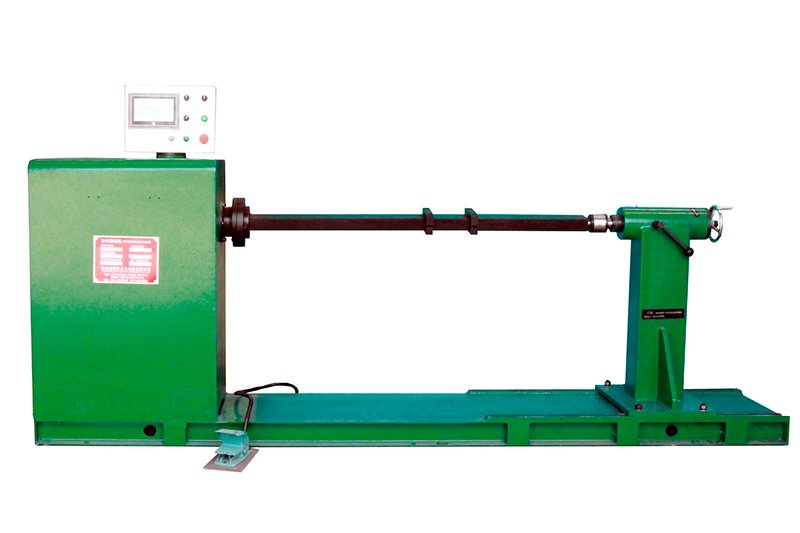

- CNC control semi automatic transformer winding machines–

The cnc control transformer winding machines are updated version of winding machine. There machines have a motor and reducer, winding speed up to 240 or 450rpm. In these machines, wires can be guided automatically. With a touch screen,you can easily operate.

These transformer winding machines has types to wind copper and aluminum wire , also has types to wind copper and aluminum foil.

- Automatic transformer winding machine

the automatic transformer winding machines do the winding job with less need of human interference. The advantage is these types of winding machines can help reduce the labor costs.